Top Human AI Engineers for your Vision AI projects.

Our vision AI agent power's South Korean Cars

Every car that comes out of the factory are AI-visually OK by our code. 100% accuracy for every variant, every time..

The Red and Blue cans factories use our AI Vision algorithms

95% accuracy is easy, 100% accuracy requires consistency and functional skills.

End to End Factory Process Monitoring with CCTV cameras

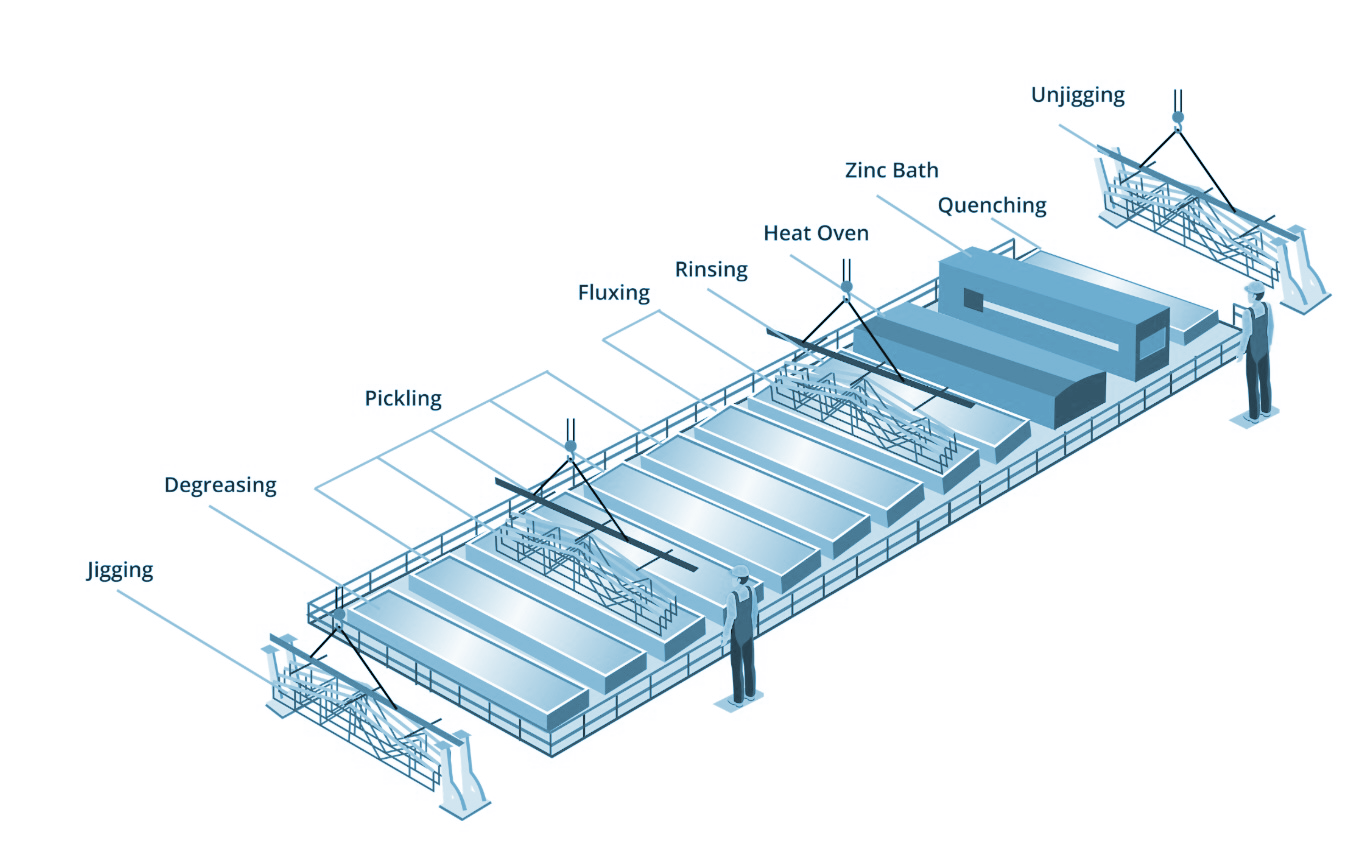

Transforming Galvanizing factories with our Vision AI algorithms: Setting new standards in Process optimization, Safety, and Industry 5.0 Integration.

AI Vision Engineering Skills

Very few companies in this World have implemented Vision AI engineering for real. We proudly belong to them

NVidia VideoLLava/Vita 2.0

Cutting-edge AI tools for real-time video analysis, object detection, and scene understanding

LLM-NIM LLAMA-3-70B

Powerful 70B-parameter language model for complex natural language understanding and generation

NVidia Physical AI

Advanced AI for simulating physical environments, enabling realistic robotics and automation

Edge AI Development

Deploying robust AI models on edge devices for low-latency, real-time decision-making

QA with Visual Inspections

Automated quality assurance using computer vision to detect flaws and anomalies

Automatic Robots movements

AI-powered robots capable of precise, adaptive, and efficient motion control in dynamic settings

About Us

When F100 trust us mean, we deliver value for them

While many talks about vision AI in the air, we have implemented it in real-time and its used everyday every second at places across the World. Be it the complex obejcts detections algorithms, visual paramters mapping and tight work flow integrations, we have done it.

What we bringing to the table is go-live expertise for you.

- Innovative problem-solvers

- Real results

- Collaborative visionaries

Blog Posts

NVIDIA Omniverse: Transforming Industries with actionable Insights

Lorem ipsum dolor sit amet consectetur adipisicing elit. Natus eligendi nobis ea maiores sapiente veritatis reprehenderit suscipit quaerat rerum voluptatibus a eius.

Zero-Shot Object Detection and Autodistill Models

By combining powerful AI capabilities with real-time 3D design, Omniverse is reshaping workflows across industries, from product design and manufacturing..

Neural Architecture Search (NAS) in Automated ML

In the era of Industry 5.0, the convergence of Artificial Intelligence, Internet of Things (AIOT), and industrial safety has revolutionized the manufacturing landscape..